The Main Principles Of 3D Printing Rapid Prototyping Services - AnyShape

Custom Prototypes Creates a Unique Metal 3D Printed Faucet - 3DPrint.com - The Voice of 3D Printing / Additive Manufacturing

Some Known Details About 3D printing prototypes: How to improve your

Metal casting can produce intricate shapes with features such as Parts are normally near-net shape, with minor post-processing needed, if any. Compared to The Latest Info Found Here manufacturing procedures, casting is more pricey in medium-to-small amounts, due to high die expense. Another downside to metal casting is that the surface area finish is relatively coarse and not appropriate for mating user interfaces.

With additive production prototyping, parts can be made in a matter of days-- permitting effective style modification and quicker time to market. With less dependence on secondary processing, 3D metal printing prototyping saves money and time. 3D printers require less attention during production, so operators don't need to be present throughout.

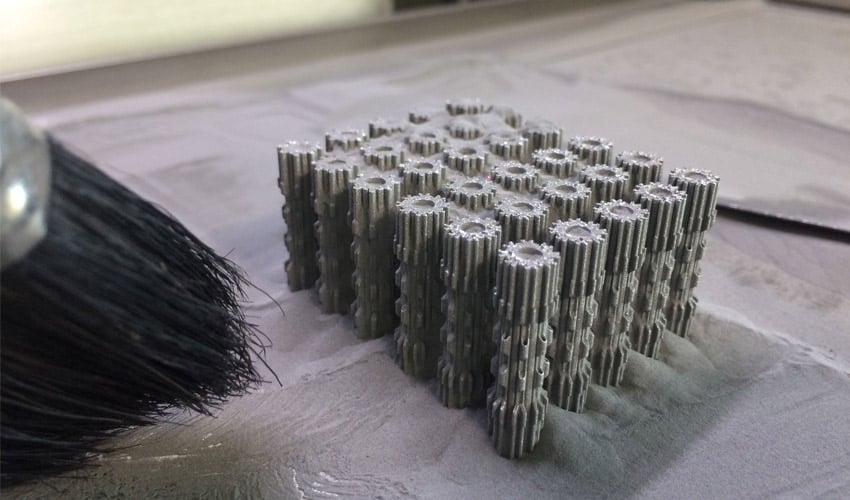

Additive manufacturing quick prototyping produces trusted, top quality parts. 3D metal printing enables intricate styles, such as intricate curves, shapes, or cavities, that standard production processes can't deal with. Tooling (jigs, components, mold inserts, etc) typically has intricate geometry. Tooling produced through CNC machining can cause making congestion, due to a limited variety of makers and operators.

Which Metal Part Prototyping Technique Should You Select? Your concept may look great on paper, but how does it hold up to real-life difficulties? Rapid prototyping and additive manufacturing enables you to check the component prior to sending it off to your consumer, saving time and money. The model method you pick will depend a lot on the type of part being produced, what its application(s) will be, and the volume of parts needed.

9 Simple Techniques For Top Metal 3D Printing Services - All3DP Pro

To get more information about whether additive production can support your product advancement, contact us.

Metal 3D Printing - SLM - DMLS - 3D Printing at Materialise

Manufacturing Tooling For companies that produce making tooling, 3D printing can be a vital resource, permitting them to rapidly and inexpensively produce complex, custom tooling and quickly replace tools when needed, reducing downtime on manufacturing lines.

Industrial Metal Molds Custom Made By SLM SLS rapid prototyping Laser 3D Printing

For Built-Rite, the Desktop Metal Studio System introduces the ability to make quick-turn mold assembly parts with a metal 3D printing procedure that is far less labor-intensive than other equipment in their factory and more cost competitive than a third-party prototyping firm.

3D Printing Industry asked 100 additive manufacturing leaders to recognize how 3D printing will develop throughout the next 10 years. In our short article last week, we had a look at the near term patterns in 3D printing to expect 2020. This brand-new article draws on insights from additive manufacturing specialists throughout the globe to comprehend where our industry is heading.